The physics of air pumps designed

for real vacuum service

The mechanical requirements for air pumps for vacuum service

are the following:

( 1 ) Flow of already very thin air should not be impeded

by any pump inlet check valves.

( 2 ) The machine must have the ability to capture, compress

and exhaust the air away from the

chamber being

evacuated.

First lets find out what is so special about a traditional

"vacuum pump".

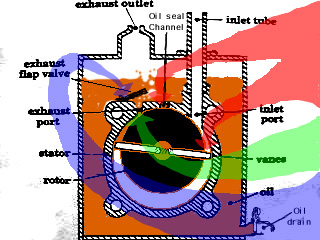

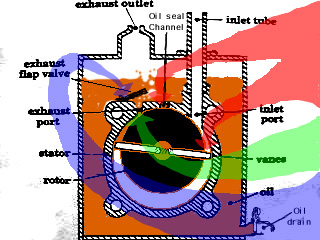

Here is a more complete diagram of a traditional rotary vane

pump used for vacuum service.

Illustrations of such machines abound in many books

relating the use of vacuum in

various scientific and industrial applications.

Those diagrams are often overly simplified and fail

to show the role that the oil plays in

the pump's operation.

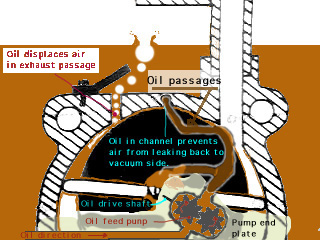

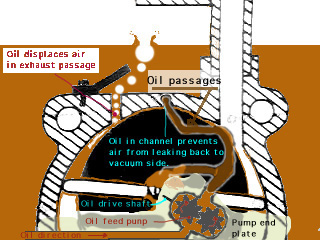

Diagram that shows how the oil seals and lubricates

working parts.

|

The oil not only serves

to lubricate the

machine, but also forms the dynamic

seals that prevent the air from leaking around

the rotor, stator and the vanes of the pump.

Another important detail often left out

is the

role that

the oil plays in displacing the air in the

passage that leads to the flap valve.

The function of the reed flap valve is

grossly understated in many texts.

This valve prevent the oil from being

sucked

( surging )

back into each arriving crescent of rarefied

air space and ramming the approaching vane.

Also, if the space in front of the

arriving vane was completely filled with

oil, the pump would be vary hard to

turn

owing to the fact that oil is thicker than

air.

The oil would have to be squeezed back

out

that small hole. |

A precise amount of oil is feed into each rotation

of the vacuum pump rotor. |

A separate oil pump that is driven from the main shaft

of the machine feeds

channels in the end plates that cover the

pump cavity pass the oil to the stator

and rotor parts.

|

Understanding of the physics of traditional "vacuum

pump" operation allowed the design

of a viable alternative.

<---- Back to main page

<-- Back to previous page Next

page-->