from the aquarium store.

Parts shopping list.

The first and most important part of this pump is the hose.

This hose must be strong enough to hold its shape

with vacuum inside yet be soft

and compliant to allow squeezing with the brayers.

( 1 ). The main hose:

The original pump design used a two

foot length of surgical tubing. The smaller diameter

stock will generally

hold up with vacuum inside.

Larger diameters must have proportionally

thicker walls. Most larger diameter hoses will have

relatively thinner walls and will have a

tendency to collapse and will not rebound under

atmosphere pressure with vacuum inside.

Hospital supplies that carry

rubber surgical tubing should be available in or near most towns.

Aquarium and fish stores now

have silicone tubing to replace the older clear vinyl that tended

to outgas plasticizer vapors into the fish

tank.

This tubing measures about 1/8Th

of an inch inside and 5/16 th. of an inch outside

diameter.

I purchased the hose from

a dive shop. One can also try a sporting goods store.

The hose is called "Sling material".

This kind is black in color and measures 3/16 th of an inch

inside by 3/8 of an inch outside diameter.

It was priced about a

dollar per foot.

| This hose is from the dive shop. |  |

The lighter colored hose is

from the aquarium store. |

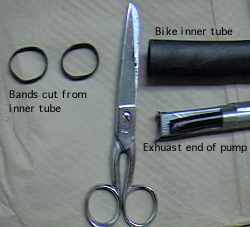

( 2 ). Thick short wide rubber bands.

The short and wide colored rubber bands that are used to tie broccoli and

other vegetables

will work for use in forming the check valve, however it has been found

that the rubber of

these bands will not endure heavy repeated contact with the brayers.

A suggested alternative to those are sections cut from discarded bicycle

tire inner tubes.

These may be found in the trash can of a bicycle repair shop or bike outfitter

store.

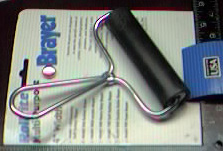

( 3 ). Brayers.

These can be purchased from an art supply store. There are several kinds

of brayers for

different ink bases. Avoid the older gelatin rollers for spreading oil

based printing inks.

I have found several kinds, the hard solid clear plastic, the medium,

soft solid rubber

and a foam type. The medium 4 inch one is the least expensive and sells

for $5.00 apiece.

It is recommended that the end bearings of the brayer are

greased before the heavier than

normal use begins.

( 4 ). Stick of wood.

The stick that I use in my version is called a "parting bead". This is

the strip of wood that

separates the upper outer and the lower inner window sash tracks in an

older style window.

This particular stock of wood measures 3/4 of an inch wide by 3/8 of an

inch thick.

A three foot ( a yard or meter ) long piece will do.

This stock has pre rounded edges so one does not have to do any sanding.

Any stick of appropriate dimensions will work, but one will have to sand

the edges before

assembly. Lumber yards and building supplies

offer a wide range of stock.

( 5 ). Duct or Gaffer's tape.

Also available from a hardware store is a typical roll of two inch wide,

general

purpose utility tape.

Others tapes like packing tape can be used if they can withstand

repeated flexing and contact with the brayers.

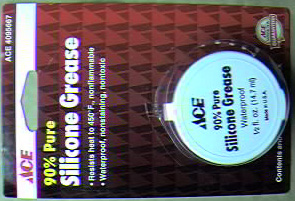

( 6 ). Silicone faucet grease. ( Optional

pump sealant and lubricant )

This is usually found in the plumbing section of a hardware store. It is

normally

applied

to the threads and packing gland around the stem of a faucet

handle.

According to the vender, silicone grease will not harm the rubber of the

hose.

Some small amount of this grease helps prevent the air from seeping through

the

brayer

pinched hose.

This lubricant was purchased in Dec.2000 in S.F. CA. |

This particular batch was a little on the runny side. |

I have added up my cost for building the pump.

Prices are very approximate as of Feb 2001

in San Francisco. Actual prices of materials will

vary depending on the time and location of the

purchase.

A question mark in the cost column means that I

have gotten that item for free.

|

( 1 ). The main hose

$ 2

( 2 ). Thick short wide rubber bands

?

( 3 ). Two Brayers

$ 10

( 4 ). Stick of wood

$ 2

( 5 ). Duct or Gaffer's tape

$ 3

( 6 ). Silicone faucet grease

$ 3

________________________________________

( 1 ) Linear peristaltic air pump

around $ 18

|

<------ Back to vacuum Introduction

<--- Back to previous page

To next page --->